Specialists in Electric and Hybrid Vehicles

The only operator with 6 levels of specialisation!

The only operator with 6 levels of specialisation!

Specialists in EVs and PHEVs

This course aims to train specialised technicians to ensure the correct reception of electric and hybrid vehicles in accordance with European safety standards and regulations. Professionals trained through this programme acquire essential skills to carry out work on electric and hybrid vehicle systems that are not directly related to high-voltage components or systems.

The main topics covered include:

- Defining the basic principles of electricity.

- Explaining how electric vehicles work.

- High-Voltage System Safety: Course participants learn how to handle high-voltage systems safely, with a strong focus on accident prevention and personal protection.

- Non-High-Voltage Systems: Participants are trained to work on electric and/or hybrid vehicle systems that do not involve high voltage, such as brakes, suspension, and other essential areas.

- Standards and Regulations: The course covers specific safety standards and regulations for electric and hybrid vehicles.

This course aims to train specialised technicians in the de-energisation of High-Voltage Systems in Electric and Hybrid Vehicles, providing them with the following skills:

- Deactivation of high-voltage systems: Participants learn how to safely deactivate high-voltage systems, ensuring risk prevention during maintenance procedures.

- Safe activation of high-voltage systems: The course also covers how to safely reactivate high-voltage systems, ensuring energy is restored in a controlled and secure manner.

- Applying procedures for energy verification and system isolation: Technicians are trained to apply rigorous procedures for verifying energy and isolating systems, ensuring that the system is fully de-energised before any intervention.

- Verifying the operation of high-voltage systems: In addition to maintenance, the course teaches how to verify the correct operation of high-voltage systems following intervention, ensuring everything is in full compliance.

- Interpreting the operation of a battery during charging and discharging.

- Understanding the cooling and heating processes of high-voltage batteries.

This course is designed to train Technicians in the Diagnosis, Maintenance, and Repair of High-Voltage Systems in Electric and Hybrid Vehicles.

To enrol, technicians must have successfully completed Levels I and II or possess an equivalent curriculum, subject to evaluation by our trainers.

This is the only course that legally qualifies professionals to access high-voltage systems, understanding the associated risks and their intrinsic operation.

The analysis of electronic systems using the latest technology allows for faster and more accurate diagnostics, offering a key advantage over emerging competitors.

The main topics covered include:

- Carrying out repairs and maintenance on deactivated HV systems: Participants acquire essential skills for repairing and maintaining high-voltage systems that have been safely deactivated, covering both mechanical and electrical aspects.

- Maintenance and Repair: Technicians are trained to diagnose issues and perform maintenance on various high-voltage systems in the vehicle, including mechanical, electronic, and electrical components.

- Understanding the general aspects of maintenance in hybrid and electric vehicles.

- Explaining the concept of magnetism.

- Explaining how high-voltage batteries work.

- Safely working on energised components.

This specialised course ensures that technicians acquire the skills to operate high-voltage battery diagnostic equipment that is technologically leading and internationally recognised for its reliability and precision. The exclusive use of manufacturer-approved instruments — such as the EVA BT3562A, EVA BT4560, SW1001, EVA GRX5100, EVA MS800(A) and EVA MS801 — guarantees consistent measurements in line with the highest industry standards.

The training combines intensive hands-on practice with the rigorous application of certified safety procedures, enabling participants to perform critical measurements — voltage, capacity, charge/discharge currents, internal resistance and Cole-Cole Plot analysis — and interpret them accurately and with sound technical reasoning.

With this technical expertise, professionals will be able to carry out complete diagnostics, identify faults with high precision, and propose effective solutions, ensuring that the reliability of the tests is matched by a thorough interpretation of the data — an essential condition for effective interventions in electric and hybrid vehicles.

This is state-of-the-art technology used by the world’s leading companies and industries, such as Lockheed Martin, NASA, Samsung, ABB, Jaguar Land Rover, OTIS, Mitsubishi, and others.

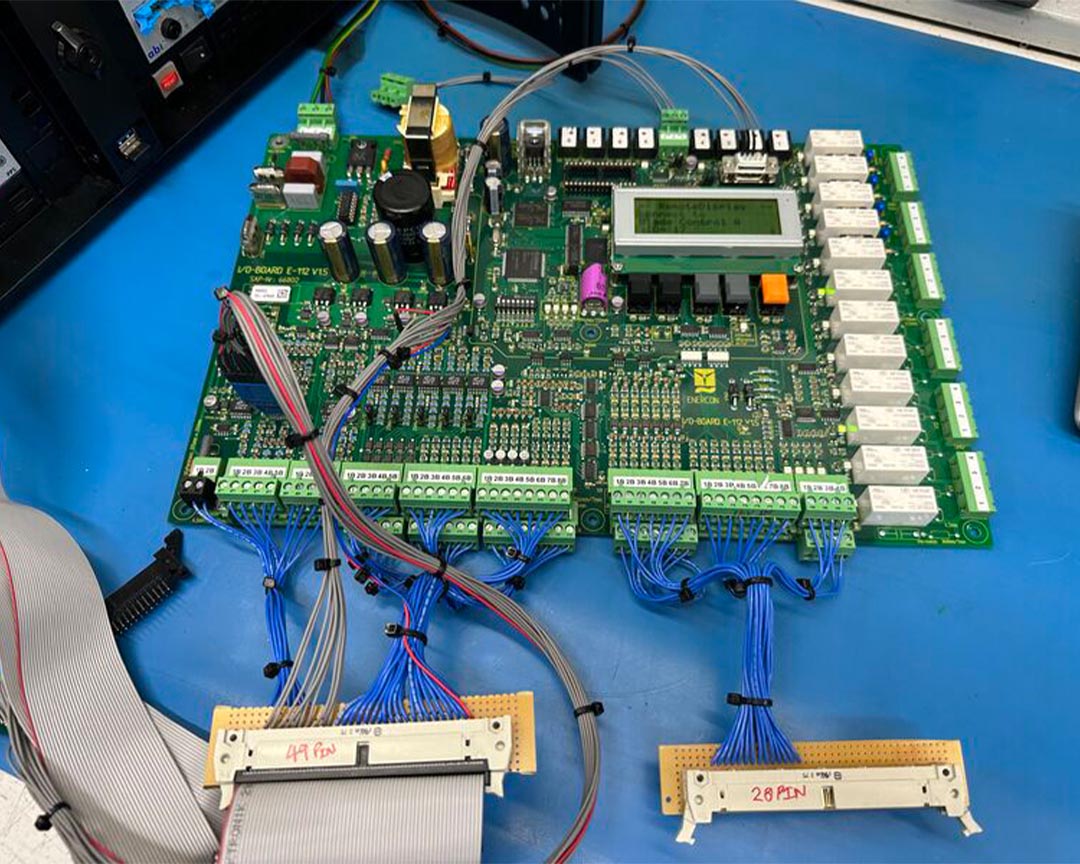

It is the most advanced proprietary technology in the world, enabling the rapid detection and identification of faulty components in a circuit, allowing for fast, accurate, and cost-effective repair.

With the ongoing disruptions in global supply chains for components across various industries — including the electric vehicle sector — this solution offers a way to gain independence from suppliers.

This technology enables you to always keep in stock the most frequently used or hardest-to-source printed circuit boards for all types of electronic circuits.

This module provides an effective method for creating high-quality circuit diagrams from a sample board. The EVA Level 6 system comprises a PC-controlled continuity measurement hardware system, the SYSTEM 8 Ultimate control software, and EdWin XP, a complete CAD package.

It identifies the connectivity of a sample circuit and generates a Net List (a list of components and connections). The Net List is then imported into EdWin XP to produce high-quality circuit diagrams. A unique solution in the sector, and yet another innovation from EVA Labs.

Training for the preparation of Certified Collision Interventions on Electric Vehicles, in accordance with the specific framework, European legislation, and OEM manufacturer requirements.

Qualification to carry out safety diagnostic procedures, de-energise, disassemble and reassemble a high-voltage battery, disconnect auxiliary components, perform torque-controlled tightening, adjust differential equalisation bolts, purge cooling systems, and drain and refill gas and coolant — culminating in the issuance of a Battery Disassembly Certificate.

Electric Vehicle Collision Intervention Preparer.

Includes:

1) One-day Certified Professional Course leading to the professional qualification TPCVE – Collision Preparer Technician for Electric Vehicles.

2) One-day Certified Professional Course as a user of the SiGMA Software.

John Lasseter, Pixar