Advanced and In-Depth Battery Diagnostics

The first and most comprehensive high-voltage EV/HEV Battery service tool in the industry, the EVA5100 Dynamic Balancer performs full-service maintenance for Electric and Hybrid Vehicle batteries.

Key Features:

The EVA MS800A is an innovative tool designed for the maintenance of electric and hybrid vehicles, developed to identify faulty modules in high-voltage batteries.

Ideal for specialised workshops and technicians, this device enables the evaluation of nickel-metal hydride (Ni-MH) and lithium-ion (Li-ion) battery module capacity, making it easier to identify potential repair needs. With the growing demand for battery repair services, the MS800A stands out as an essential tool to ensure the efficiency and longevity of electric vehicle energy storage systems.

The EVAMS801 tester was developed exclusively for diagnosing lithium-ion battery modules in high-voltage electric and hybrid vehicles, as well as 48-volt batteries in mild hybrid electric vehicles (MHEVs).

It operates in automatic mode, following the user-defined criteria.

The EVA MS800 is the most comprehensive and advanced tool on the market for the maintenance of electric and hybrid vehicles, developed to identify faulty modules in high-voltage batteries.

Ideal for specialised workshops and technicians, this device allows the evaluation of nickel-metal hydride (Ni-MH) and lithium-ion (Li-ion) battery module capacity, making it easier to identify potential repair needs. With the growing demand for battery repair services, the EVA MS800 positions itself as an essential piece of equipment to ensure the efficiency and durability of electric vehicle energy storage systems.

The EVA BT3562A is a high-precision battery testing instrument, ideal for in-depth assessment of the condition of individual cells and battery packs. With the ability to simultaneously measure internal resistance and open-circuit voltage, it enables a detailed evaluation of battery integrity and performance.

Key Features:

The EVA BT4560 is a high-precision impedance meter, ideal for detailed measurements of battery cells and packs. With the ability to simultaneously measure impedance, voltage, and temperature, it provides in-depth analysis of internal resistance and electrochemical reactions within the batteries, allowing for accurate identification of cell faults.

The EVA DM7276 is a high-precision DC voltmeter, ideal for rigorous testing of lithium-ion batteries and other next-generation devices. With 9 ppm accuracy, simultaneous temperature and voltage measurements, and advanced thermal compensation features, it delivers reliable and consistent results even in environments with temperature fluctuations.

Key Features:

As a global leader, Hioki supports the production, development, and maintenance of batteries through reliable measurements that sustain today’s battery technologies while leading the way into the future. In production processes, its products ensure consistent quality by measuring battery internal impedance and OCV with high precision and minimal variability. In R&D applications, the equipment enables the measurement of parameters that were previously impossible to quantify, including interface resistance and high-precision battery impedance analysis. In maintenance applications, the products streamline battery diagnostics while supporting the shift towards predictive maintenance.

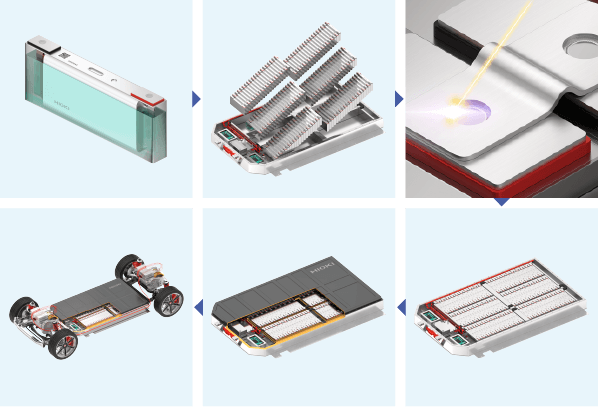

Inspection During Li-ion Battery Assembly for EVs

Detection Methods for Lithium-Ion Batteries Containing Ignition Risk Factors

Lithium-Ion Battery Insulation Resistance Test

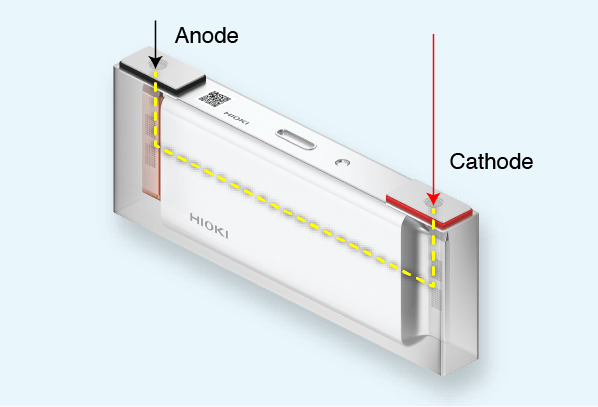

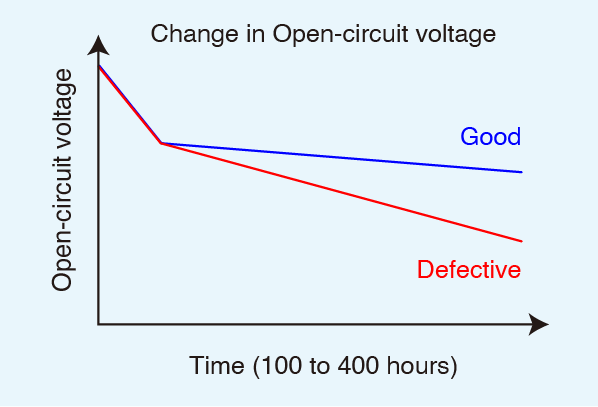

Lithium-Ion Battery Open-Circuit Voltage (OCV) Test

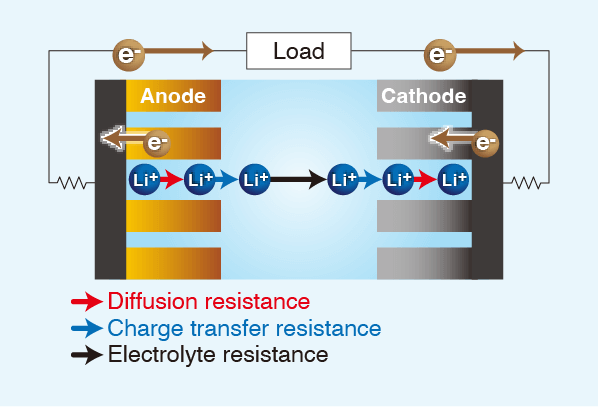

Lithium-Ion Battery Internal Resistance Test

Lithium-Ion Battery Weld Quality Test

Why is it important to measure a battery’s internal resistance?

Learn why it is important to measure a battery’s internal resistance during the battery production process and throughout its operation.

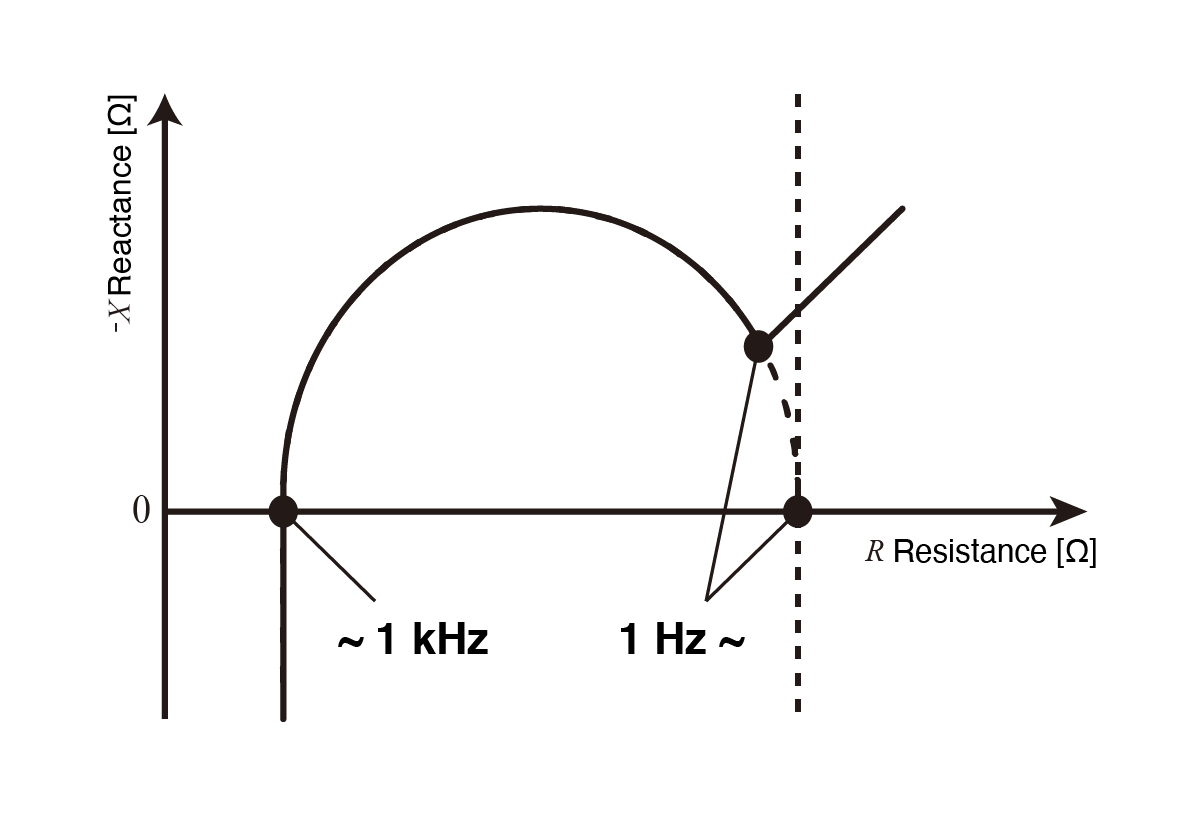

Nyquist Plot for Lithium-Ion Battery Impedance Measurement

A Nyquist plot is a graph that plots impedance values measured at multiple frequencies. Learn how it is used in lithium battery analysis.

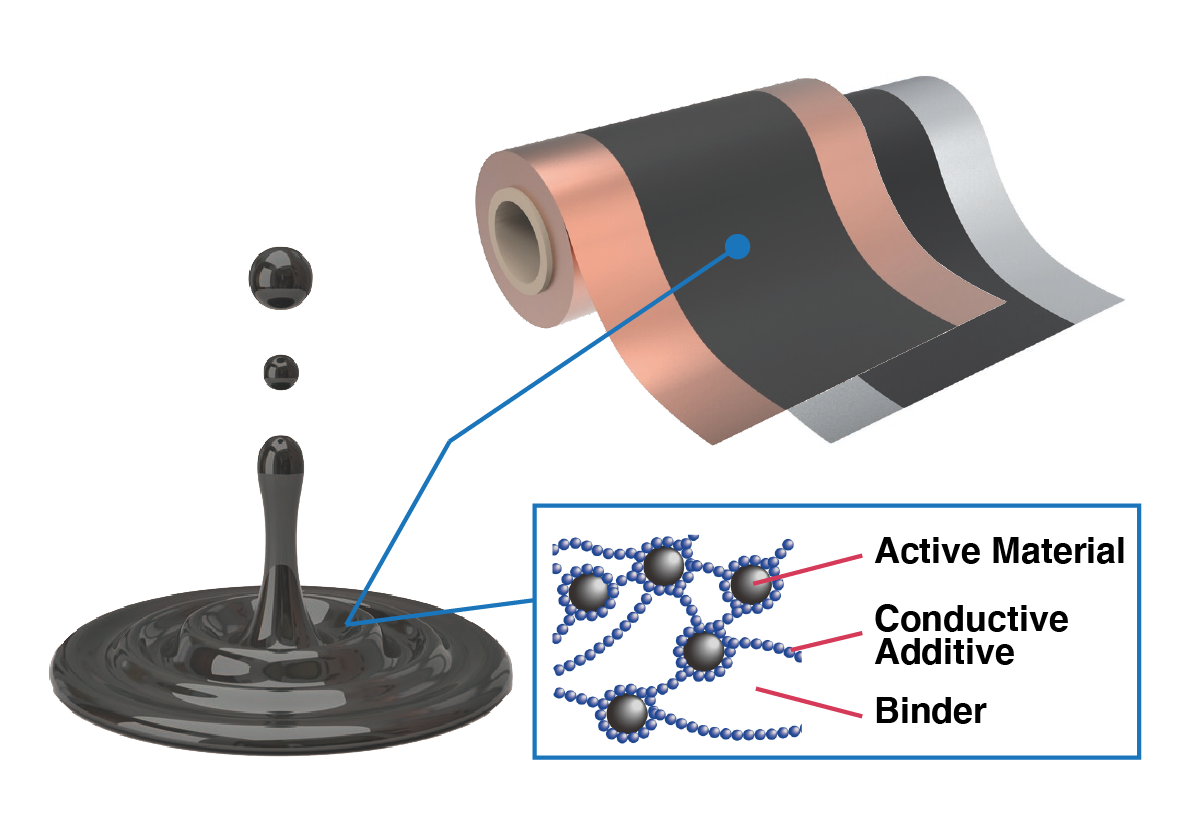

What is the electrode paste of a lithium-ion battery?

The electrode paste is applied to the metal foil to create the electrode sheet of the lithium-ion battery. Learn more about electrode paste materials and their role.

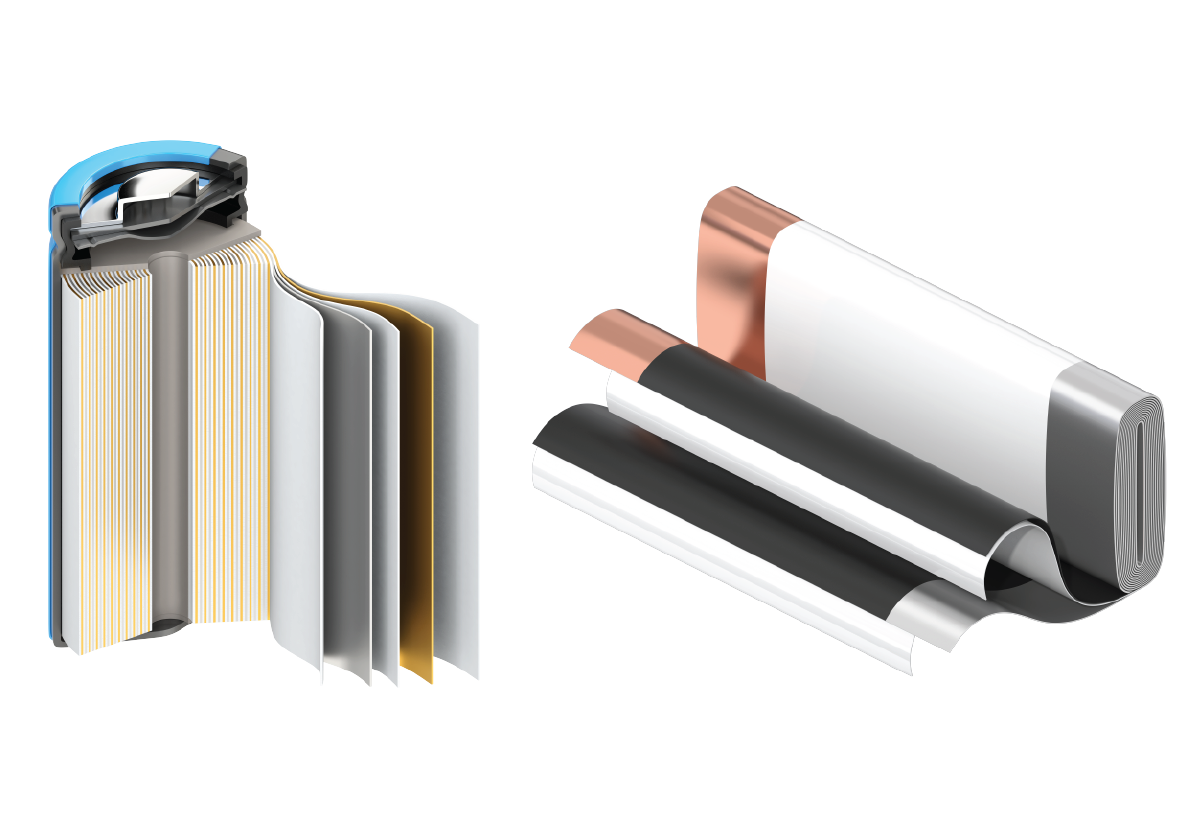

Which electrode foils greatly affect the quality of lithium-ion batteries?

As a battery component, the electrode foil has a significant impact on its overall performance. Learn more about this fundamental component.

All content on this page is authored and the responsibility of Hioki EE Corporation (Japan).