Diagnosis and Repair of Complex Electronic Circuits

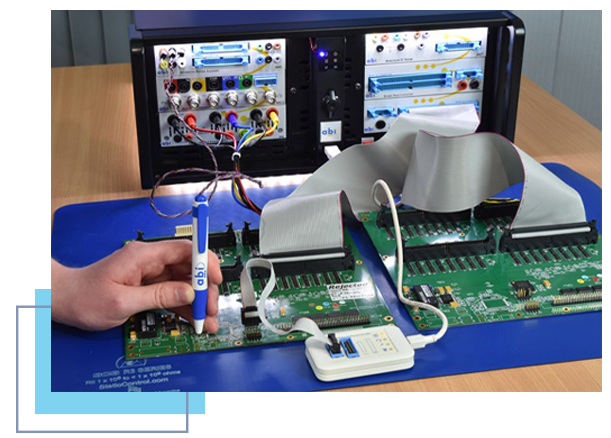

The 19” BoardMaster Rack Universal Diagnostic System is a versatile, standalone, and easy-to-use universal diagnostic pack. It offers the most comprehensive set of testing instruments to detect faults in almost any type of PCB (Printed Circuit Board). This is a preferred product for companies operating in the automotive, aerospace, military, and a variety of other industrial sectors. The BoardMaster is the supplier’s most complete solution, saving customers time and money while increasing asset availability and reliability.

With a full range of instruments and a variety of testing methods that ensure a fail-safe system, the BoardMaster 19" Rack provides users with the most advanced PCB diagnostic tool on the market.

The BoardMaster 19" Rack includes the pre-installed SYSTEM 8 Ultimate software, featuring multiple and easy-to-use licences. This powerful yet user-friendly software includes user access management, the exclusive TestFlow Manager, and a wide range of customization options.

The JTAGMaster Tester and Programmer is a fully integrated solution for the configuration and diagnosis of Programmable Logic Devices (PLDs).

This pack includes:

The JTAGMaster is also capable of programming EEPROM devices using external adapters. Standard binary files are supported and can also be modified in the device buffer window. A wide range of EEPROM devices is included in the library, which can be easily customised by users. The following protocols are supported by the JTAGMaster:

RevEng offers an effective method for creating professional-quality circuit diagrams from a sample board. The RevEng system consists of PC-controlled hardware for continuity measurement, the SYSTEM 8 Ultimate control software, and EdWin XP, a comprehensive CAD package with advanced features.

RevEng captures the connectivity of a sample circuit and produces a connection list. This list is then imported into EdWin XP to create professional-quality circuit diagrams.

The capture process is carried out using clips, connectors, and probes attached to groups of components. SYSTEM 8 Ultimate guides the operator in placing and moving the clips around the reference circuit. An efficient sequence of clip combinations and movements is then generated to map all possible connections.

To minimise operator errors, the system applies orientation and pin checks to confirm clip contact and position. RevEng learns without applying power to the board and limits the voltage and current applied so that semiconductors are not affected — it is also safe to use on low-power technologies. There is a wide variety of clips and IC connectors available. If a clip or connector is not available or cannot be installed due to the board’s physical constraints, manual probes and audio feedback are used.

This pack includes:

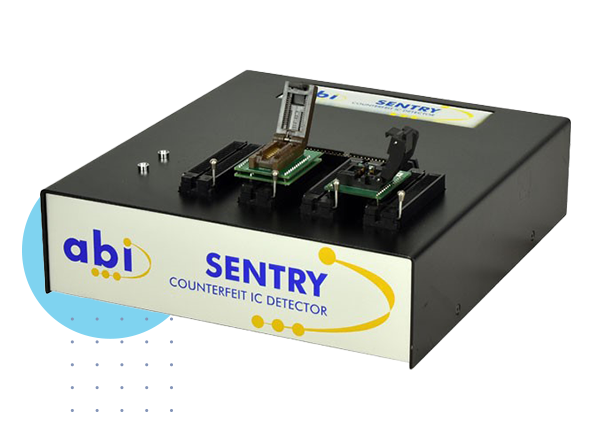

SENTRY is a unique solution for the quick and easy detection of counterfeit integrated circuits (ICs) and components. With over 34 years of experience in the field of test and measurement equipment, as well as in electronics manufacturing, the manufacturer designed this product based on two main concepts:

This pack includes:

The cost of repairing a circuit board is, on average, about 10% of the price of purchasing a new one. So why do we continue to discard them so easily?

On-site repairs with zero emissions

An investment in training and the right diagnostic technologies can transform small businesses into local repair benchmarks, capable of testing, maintaining, and repairing electronic components in-house. Costs can be reduced by up to 90% compared to purchasing parts directly from the original equipment manufacturer (OEM).

Return on Investment

Local laboratory setups require a substantial investment in equipment, training, and infrastructure. Most companies involved in the “Repair Don’t Waste” movement recoup their investment within 12 to 24 months, sometimes even sooner.

Sustainable Impact

Choosing to repair rather than purchase new components reduces emissions by 85%. The UN estimates that approximately 50 million tonnes of electronic waste will be produced in 2023 alone. This waste is valued at €50 billion solely in materials. In-house repair, along with the reduction of electronic waste, adds immense value to companies committed to the energy transition.